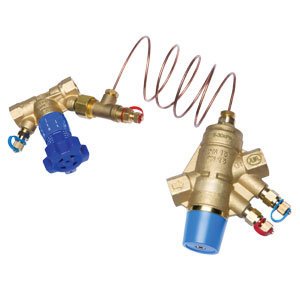

Dynamic Brass Valves

Granbalance (ADL, Russia)

DN 15–50 mm

PN 2.5 MPa

t°op –10 ....+120°C

Connection type: Coupling.

Applications: automatic balancing, regulation and limitation of heat carrier flow in heating, cooling and conditioning systems filled with water or ethylene glycol (up to 40%)/water mixture.

Description:

Intended to maintain constant differential pressure in pipelines of heating and cooling systems. Valves installed in variable flow systems ensure constant nominal flow of the heat carrier passing through instruments to eliminate their mutual influence.

This solution contributes to accurate regulation of the indoor temperature and reduces the risk of noise generated by regulators under high pressure drop (Δp).

Combination with a partner valve enables to control the heat carrier flow across the loop.

Type: KBA, Series 20.

Static Cast Iron Valve

Granbalance (ADL, Russia)

DN 65–300 mm

PN 1.6 MPa

t°op –10 ....+120°C

Connection type: Flanged.

Applications: hydraulic balancing, regulation and limitation of heat carrier flow in heating, cooling and conditioning systems filled with water or ethylene glycol (up to 40%)/water mixture.

Description:

Valves ensure energy saving and heat carrier flow required for optimal operating temperature and smooth system operation, as well as increase service life of the system and considerably reduce fault rate.

Key advantages: setting fixation; complete closure without further reconfiguration; complete shut-off of the pipeline; optional mounting position; high capacity; two dials (coarse/fine) for easier tuning.

Static valves fitted with a measurement drain nipple (available upon request) may be used for draining.

Type: KBCh, Series 10.

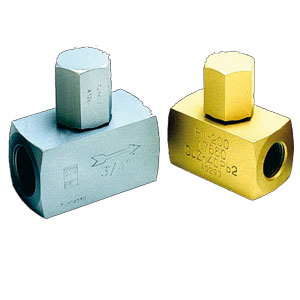

Static Brass Valves

VIR (Italy)

DN 15–50 mm

PN 2.5 MPa

t°op –10 ....+130°C

Connection type: Coupling.

Applications: hydraulic balancing, regulation and limitation of heat carrier flow in heating, cooling and conditioning systems filled with water or ethylene glycol (up to 40%)/water mixture.

Description:

Valves ensure energy saving and heat carrier flow required for optimal operating temperature and system performance, as well as increase service life of the system and considerably reduce fault rate.

Key advantages: setting fixation; complete closure without further reconfiguration; complete shut-off of the pipeline; optional mounting position; high capacity; two dials (coarse/fine) for easier tuning. Static valves fitted with a measurement drain nipple (available upon request) may be used for draining.

Type: VIR 9505, VIR 9506, VIR 9515.

Lined Ball/Plug Valves

Swissfluid (Switzerland)

DN 15–150 mm

Pop. 0.1 kP…1.6 MPa

t° –40…+200°C

Connection type: Flanged.

Applications: pipelines for transportation of chemically active, aggressive and abrasive fluids; powders in chemical and pharmaceutical industries, metallurgy, food industry and other sectors.

Description:

Leakage class A, GOST R 54808-2011; special design of stem dynamic seal. Customized regulation options. Body lining: PFA (standard option), PFA-AS (antistatic option), PVDF, PP, ETFE.

Ball/plug lining: PFA (standard option), PFA-AS (antistatic option), PVDF, PP, ETFE.

Body materials: WCB Carbon Steel, AISI 316 Stainless Steel.

Ball material: Duplex Stainless Steel (standard option), Titanium, Hastelloy.

Actuators: bare stem, handle, electric or pneumatic actuator.

Version: SBV, SCP.

Three- and Four-Way Ball Valves

Orbinox (Spain)

DN 80–300 mm

PN 1.0 MPa

Connection type: Flanged.

Applications: pulp and paper industry (for pulp transportation).

Description:

Distribution valves 3V and 4V are designed to transport fluids containing solid particles.

Valves come with stiffeners to reinforce the structure. The interior design solution prevents the build up of foreign particles which impede the closure of the valve.

Valve cover is made of stainless steel. High precision machining of the inner part of the valve cover contributes to complete tightness of the system, even for transportation of 4% pulp.

Body materials: Cast Iron, Stainless Steel.

Sealing materials: metal/metal.

Actuators: handwheel/gearbox, double-acting pneumatic actuator, electric actuator.

Versions: 3V, 4V.

Three- and Four-Way Ball Valves

Pekos (Spain)

DN 25–600 mm

PN 1.6–40 MPa

ANSI 150–2500 Lbs

Connection type: Flanged.

Applications: energy sector, chemical industries, pulp and paper industry, mining, steel production, food industry, pharmaceutical and fragrance industries and other sectors.

Description:

Leakage class A; fireproof design; maintenance-free stem with drop-out protection.

Body materials: Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, special alloys.

Sealing materials: PTFE, PTFE + Graphite, PTFE + Glass Fiber, metal with chromium carbide coating, PEEK, special polymers.

Actuators: handle, gearbox, electric and pneumatic servo actuators.

Versions: P8, Р7.

Three-Way Ball Valves

BV (ADL, Russia)

DN 8–50 mm

PN 4.0–6.3 MPa

Connection type: Thread.

Applications: chemical industry, food industry, pulp and paper industry, mining, steam and condensate systems; water supply systems.

Description:

Leakage class A; reduced bore pattern.

Body material: Stainless Steel.

Sealing: PTFE + Graphite.

Versions: BV3.

Two-Way Ball Valves

Pekos (Spain)

DN 8–600 mm

PN 1.6–40 MPa

ANSI 150–2500 Lbs

Connection type: Flanged, Wafer, Welded, Thread.

Applications: energy sector, chemical industries, pulp and paper industry, mining, steel production, food industry, pharmaceutical and fragrance industries and other sectors.

Description:

Leakage class A; fireproof design; maintenance-free stem with drop-out protection.

Body materials: Cast Iron, Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, special alloys.

Sealing materials: PTFE, PTFE + Graphite, PTFE + Glass Fiber, metal with chromium carbide coating, PEEK, special polymers.

Actuators: handle, gearbox, electric and pneumatic servo actuators.

Versions: P0 (DIN), P1, P3…P25 (ANSI), PW, PH, P56, K8, etc.

Two-Way Ball Valves

BV (ADL, Russia)

DN 8–150 mm

PN 1.6–10.0 MPa

Connection type: Flanged, Wafer, Welded, Thread.

Applications: chemical industry, food industry, pulp and paper industry, mining, steam and condensate systems; water supply systems.

Description:

Leakage class A; two — and three-piece design; full or reduced bore pattern.

Body material: Stainless Steel.

Sealing: PTFE + Graphite.

Versions: BV15, BV16, BV17, BV18.

Lined Valves

Swissfluid (Switzerland)

DN 25–1000 mm

Рop 0.1 kPa...1.6 MPa

t°op –40…+220°C

Connection type: Wafer.

Applications: pipelines for transportation of chemically active, aggressive and abrasive fluids; powders in chemical and pharmaceutical industries, metallurgy, food industry and other sectors.

Description:

Leakage class A, GOST R 54808-2011; special design of seat seal and stem dynamic seal.

Disc lining: PFA (standard option), PFA-AS, PVDF. Coating-free version is available upon request.

Resilient parts: silicon (standard option), FPM (Viton), EPDM.

Body materials: WCB Carbon Steel, AISI 316 Stain-

less Steel.

Disc materials: Duplex Stainless Steel (standard option), Titanium, Hastelloy.

Sealing material: PTFE, PTFE-R, EPDM, EPDM (white), Viton, NBR, SBR, VMQ.

Actuators: bare stem, handle, electric or pneumatic actuator, gearbox.

Versions: SBP, SBE.

Double Eccentric Butterfly Valves

Stainval (ADL, Russia)

DN 150–2000 mm

PN 1.0/1.6 MPa

t° –10…+80°C

Connection type: Flanged.

Applications: water supply systems, ventilation and air conditioning systems.

Description:

Double offset design contributes to reduced wear and opening torque and increases the number of opening and closing cycles.

Removable disc seal.

Leakage class A, two flow directions.

Epoxy coating, 250 μm.

Low pressure loss due to a flat streamlined disc shape.

Key connection for secure fastening of the shaft to the valve disc.

Disc materials: Nodular Cast Iron, Stainless Steel.

Body materials: Nodular Cast Iron.

Sealing materials: EPDM.

Actuators: gearbox, electric actuator.

Version: BC.

Triple Offset Valves (metal-to-metal)

Stainval (ADL, Russia)

DN 200–1200 mm

PN 1.6/2.5/4.0 MPa

t° –40…+315°C

Connection type: Flanged, Welded, Wafer.

Applications: energy sector, heating; metallurgy, pulp and paper industry and other sectors.

Description:

Ideal solution for high temperature, pressure and corrosive environments. Advantages: compact size, low weight, easy installation, automatic operation, moderate price.

Leakage class A, GOST R 54808-2011, two flow directions.

Shut-off and control function.

Body/disc materials: Carbon Steel, Stainless Steel.

Sealing materials: metal/graphite, special versions.

Actuators: gearbox, electric actuator.

Version: ТМ.

Centric Butterfly Valves

Granval (ADL, Russia)

DN 25–1600 mm

PN 1.0/1.6/2.5 MPa

t° –40…+150°C

Connection type: Wafer, Flanged, LUG type.

Applications: heating and water supply systems, ventilation and air conditioning systems, fire fighting systems. Intended for transportation of drinking and service water, seawater, food and bulk products, aggressive and abrasive media (depending on valve materials) under a wide range of operating temperature and pressure.

Description:

Stem extension option.

Leakage class A.

Body materials: Grey Cast Iron, Nodular Cast Iron, Carbon Steel, Stainless Steel.

Disc materials: Stainless Steel, Bronze, Nodular Cast Iron (with ethylene propylene lining or epoxy coating).

Sealing materials: EPDM, EPDM HT, Nitrile, Epichlorohydrin, Flucast AB/P,AB/E,AB/N, Silicone, Viton, Viton GF, Viton Bio.

Actuators: handle with position locking at 15° intervals; handle with optional position locking; gearbox; electric or pneumatic actuators.

Magnetic Coupling Version (API 685)

M-Pumps (Italy)

Qmax up to 4000 m3/h

Hmax. up to 200 mwc

Tmax. +350°C

Applications: chemical industries.

Description:

Pumps with magnetic actuator are designed for air-tight pumping toxic, explosive and other hazardous liquids. Magnetic coupling replaces sophisticated sealing mechanisms with flush liquid systems.

Maximum allowable operating system pressure for standard version and special design version is 50 bar and 1500 bar, respectively. High-temperature versions for pumping media of up to +450°С are available upon request.

Version: CN MAG-M.

Metal Liquid End Version

CDR (Italy)

Qmax up to 320 m3/h

Hmax. up to 160 mwc

Tmax. +300°C

Applications: chemical industries, pharmaceutical industry, pulp and paper industry, fabric industry.

Description:

Pumps with magnetic coupling. Liquid end material: AISI 316 L (Hastelloy C upon request). Leak-proof liquid pumping.

Options: Ex-proof version; version for pumping liquids within the temperature range of –80...+300°С; heating or cooling jacket.

Versions: UTS, HTS, ETS.

Lines and Plastic Liquid End Version

CDR (Italy)

Qmax up to 125 m3/h

Hmax. up to 100 m

Tmax. +140°С

Applications: chemical industries, pharmaceutical industry, pulp and paper industry, fabric industry.

Description:

Unique ILS (Integral Lined System) lining technology.

Pumps with magnetic coupling and end seal.

Liquid end materials: PP, PFA, PVDF, ETFE.

Versions: UCL, UTN-L, HTN, ETN, STN.

Lined Check Valves

Swissfluid (Switzerland)

DN 15–600 mm

PN 1.0/1.6 MPa

t° –40…+200°С

Connection type: Flanged, Wafer.

Applications: chemical industries, food industry, pharmaceutical industry and other sectors.

Description:

Fully lined solution.

No additional packing is required. Interface surfaces ensure high connection tightness.

Tightness testing: according to EN 12266-1. Leakage class A (GOST R 54808-2011).

Lining testing: 35 kV spark test.

Mounting options: horizontal and vertical.

Body material: Carbon Steel (with epoxy coating), Stainless Steel

Lining materials: PFA, PFA-AS (antistatic), PTFE.

Versions: SBC, SSC.

Check Valves Plunger Type

VYC (Spain)

DN 0.8–50 mm

PN 25 MPa

t° up to 400°С

Connection type: BSP Female Thread.

Applications: steam condensate systems; food industry, chemical industries and other sectors.

Description:

Check valves designed for steam, liquid, food and aggressive media applications protect pipelines against any damage caused by reversed fluid flow.

To prevent any accident, the check valves automatically shut off the reverse flow of the fluid. Lifting design solution ensures quick closure and high tightness of the valves.

Due to an additional hold down spring used to secure the valve seat, check valves may be installed both on horizontal and vertical pipelines.

Materials: Brass, Carbon Steel, Stainless Steel.

Versions: 179.

Check Valves Coupled Type

Standard Hidraulica (Spain)

DN 10–100 mm

PN 1.6 MPa

t° –10…+110°С

Connection type: Coupling.

Applications: household heat and water supply systems.

Description:

Designed for hot and cold water applications, the valves protect pipelines against any damage caused by reversed fluid flow.

To prevent any accident, the check valves automatically shut off the reverse flow of the fluid. Lifting design solution ensures quick closure and high tightness of the valves. Due to an additional hold down spring used to secure the valve seat, check valves may be installed both on horizontal and vertical pipelines.

Versions: KENT, NY.

Check Valves Thread Type

Granlock (ADL, Russia)

DN 15–80 mm

PN 1.6/2.5 MPa

t° –60...+250°C

Connection type: Thread.

Applications: heat and water supply systems, sewage system.

Description:

Body material: Stainless Steel.

Type: butterfly and spring types.

Mounting options: vertical and horizontal pipelines.

Sealing: metal/metal.

Versions: CVT16, CVS25.

Check Valves Flanged Type

Granlock (ADL, Russia)

DN 15–1400 mm

PN 1.0/1.6/4.0 MPa

t° –50...+300°C

Connection type: Flanged.

Applications: heat and water supply systems, sewage system.

Description:

Body material: Cast Iron, Stainless Steel.

Type: lifting, butterfly and ball types.

Mounting options: vertical and horizontal pipeline (depending on the version).

Sealing: metal/metal, NBR, EPDM.

Versions: RD12, RD16, RD18, RD30, RD50.

Check Valves Flanged Type

Zetkama (Poland)

DN 15–300 mm

PN 1.6 MPa

t° –15...+300˚C

Connection type: Thread, Flanged.

Applications: heat and water supply systems.

Description:

Body material: Cast Iron.

Type: lifting and butterfly types.

Mounting options: vertical and horizontal pipelines.

Sealing: metal/metal.

Versions: 277, 287.

Check Valves Wafer Type

Orbinox (Spain)

DN 40–900 mm

PN 1.0/2.5/4.0 MPa

Connection type: Wafer.

Applications: discharge sewage systems; water treatment plants; heat and water supply systems, water disposal systems; pulp and paper industry, food industry; moderately aggressive media.

Description:

One-Way check valve with tilting seat.

Key advantages: reduced face-to-face length; minimum pressure loss; minimum opening pressure; high tightness; quick response (reduced gate stroke due to tilting seat).

Options: counterweight with/without a dashpot (damper); return spring (for higher closing speed).

Body/disc materials: Stainless Steel. Other materials are available upon request.

Sealing materials: metal/metal.

Mounting options: due to its low weight, the valve perfectly suits for installation on a suspended pipeline.

Version: RM.

Check Valves Wafer Type

VYC (Spain)

DN 15–300 mm

PN 1.6/4.0 MPa

t° –60…400°С

Connection type: Wafer, Thread.

Applications: heat and water supply systems.

Description:

Designed for steam, liquid and compressed air applications.

Horizontal and vertical mounting

between flanges.

Fluid flow direction shall match the arrow on the valve disc.

Materials: Bronze, Cast Iron, Carbon Steel, Stainless Steel.

Versions: 170, 172.

Check Valves Wafer Type

Granlock (ADL, Russia)

DN 15–1200 mm

PN 1.6/4.0 MPa

t° up to 300 °C

Connection type: Wafer.

Applications: chemical industries, food industry, pulp and paper industry, mining; steam and condensate systems; water supply systems.

Description:

Designed for steam, liquid, food and aggressive fluid applications.

Body material: Cast Iron, Stainless Steel, Carbon Steel, Bronze.

Mounting options: vertical and horizontal pipelines. Make sure that the flow direction matches the arrow on the valve body.

Sealing: metal/metal, EPDM.

Versions: ZOP, CV16, CVS16, CVS40.

Wet Rotor Circulating Pumps

Granpump (ADL, Russia)

Q up to 80 m3/h

H up to 15 m

Applications: industrial and household heating systems; chillers and air conditioners; hot water supply systems.

Description:

Centrifugal pumps with wet rotor and vertical shaft.

Temperature and pressure ranges: –15...+110°С, PN 10.

Body materials: Cast Iron/ Bronze.

Pumps come with IP44 motors (2950 rpm versions).

Wet rotor solution with direct contact of the motor shaft and fluid ensures heat removal from the motor. Low noise level.

High efficiency due to smooth surface of components ensures low friction losses.

Versions: AMT, LHN.

Circulating Twin-Head Pumps

Granpump (ADL, Russia)

Q up to 1000 m3/h

H up to 80 m

Applications: fire fighting, water supplies, heating and conditioning, process line automation.

Description:

Vertical shaft centrifugal pumps.

Temperature and pressure ranges: –15...+180°С, PN 10.

Body materials: Cast Iron.

Impeller materials: Cast Iron/ Bronze.

Sealing: end seal.

Pumps come with IP55 motors (950, 1400 and 2800 rpm versions).

High efficiency due to smooth surface of components ensures low friction losses.

Versions: IPDE, IPD.

Circulating Single-Head Pumps

Granpump (ADL, Russia)

Q up to 1000 m3/h

H up to 80 m

Applications: water supply and fire fighting systems; industrial and household heating and heat supply systems; water treatment plants, chillers and air conditioners, etc.

Description:

Vertical shaft centrifugal pumps.

Temperature and pressure ranges: –15...+180°С, PN 10.

Body materials: Cast Iron.

Impeller materials: Cast Iron/ Bronze.

Sealing: end seal.

Pumps come with IP55 motors (950, 1400 and 2800 rpm versions).

High efficiency due to smooth surface of components ensures low friction losses.

Versions: IP, IPE, IP\R.

Wet Rotor Circulating Pumps

Smedegaard (Denmark)

Q up to 128 m3/h

H up to 17.5 m

Applications: industrial and household heating systems; chillers and air conditioners; hot water supply systems.

Description:

Vertical shaft centrifugal pumps.

Temperature and pressure ranges: –15...+120°С, PN 10.

Body materials: Cast Iron.

Pumps come with IP44 motors (1400 and 2800 rpm versions).

Wet rotor solution with direct contact of the motor shaft and fluid ensures heat removal from the motor. Low noise level.

High efficiency due to smooth surface of components ensures low friction losses.

Versions: EV.

Circulating Pumps

Smedegaard (Denmark)

Q up to 750 m3/h

H up to 95 m

Applications: industrial and household heating and heat supply systems; water supply and fire fighting systems; water treatment plants, chillers and air conditioners, etc.

Description:

Vertical shaft centrifugal pumps.

Temperature and pressure ranges: –15...+120°С, PN 10.

Body materials: Cast Iron.

Pumps come with IP55 motors (950, 1400 and 2800 rpm versions)

and high-quality John Crane seals. Special design contributes to low noise level. Omega Pumps provide overload-free operation at any duty point. Pump shafts come in high-quality AISI316 Stainless Steel.

High efficiency due to smooth surface of components ensures low friction losses.

Versions: Omega.

Climate Category

Grantor (ADL, Russia)

t° –40…+40°С

Applications: operation under moderate and cold climate conditions (out door version according to National State Standard (GOST 15150-69).

Description:

Versions with rain cover and pedestal options are available upon request.

Gland entries for electric cables ensure high tightness of the product.

Heating elements are installed inside the panel.

Customized versions are available upon request.

Ex-Proof Version

Grantor (ADL, Russia)

U 1 x 220 V, 3 x 380 V

Applications: mining, chemical industry and other sectors.

Description:

ADL was given a Conformity Certificate covering all Ex-proof versions of Grantor Control Panels. Ex-proof versions:

1Exd[ia]IIBT5, 1ExdllCT4, 1ExdllBT5, 1ExdIIBT6;

power of up to 132 kW;

enclosure class of up to IP66;

climate category — out door version according to National State Standard (GOST 15150-69), etc.

Customized versions are available upon request.

Input Distribution Panels

Grantor Select (ADL, Russia)

U 1 x 220 V, 3 x 380 V,

3 x 690 V

I 6–2500 A

Applications: receiving, distribution and metering of electric power (220/380/690 V AC, 3-phase, 50 Hz)

in networks with solidly earthed and isolated neutrals; line protection against overload and short circuit; protection against electrical injuries caused by accidental contact with exposed parts of the building wiring. Special design of the distribution board prevents frequent energizing/de-energizing of electric power lines within group circuits in any emergency situations.

Description:

Electrical low-voltage device for supplying, distributing and metering electric power, as well as for monitoring and protecting outgoing distribution and group electric grids of residential, public and industrial buildings. The above equipment forming functional blocks is installed in one or several panels or in one cubicle (depending on the type of connected buildings).

Marking (example): АRP40-160-416.2/216.6-54А.

LCD Touch Screen Panels

Grantor (ADL, Russia)

U 3 x 380 V

I 0.63–1500 A

P 0.37–800 kW

Applications: heat supply systems; hot and cold water supply systems; water supply and conditioning systems; control of sewage pumping stations, circulating, feed, boosting and borehole pumps. Controller for budget frequency converters.

Description:

Interactive module with a large colour touch screen for displaying a mnemonic diagram with images of components (pumps, relays, sensors), status of the system and component (operation, stop, sleep mode, accident). Module front panel is used to set the parameter values. Russian interface; help menu.

Versions: Control panel with a frequency converter (alternating master); control panel with frequency converters for each motor. Actuators: pressure sensor and dry running protection relay. Accurate control of system parameters.

Modbus RTU control option is available upon request (monitoring of operating modes of the control panel and pump status; possibility to start/stop the pumps and control panel, read frequency of the frequency converter, change the task).

Marking (example): АEP40-009-54KCh-22А; АEP40-013-54KCh3-33А.

Multifunction Panels

Grantor (ADL, Russia)

U 1 x 220 V, 3 x 380 V

I 0.1–15.5 A

P 0.06–7.5 kW

Applications: control of circulating, boosting and drain pumps, sewage pumping stations (SPS).

Description:

Motors with the nominal current of 0.1...6 A or 6...15.5 A are connected to multifunction control panel.

Single-phase (1 х 220 V) and three-phase (3 х 380 V) motors can be connected to control panels.

Versions with pressure relays, float level sensors and 4...20 mA analogue signal are available upon request.

Protection of pumps against short-circuit, overheating and dry running; possibility to connect PTC sensors; enclosure class — IP65. Selection of pump operating mode: basic mode + auxiliary or basic mode + standby mode. Extended dispatching control.

Marking (example): АEP40-006-65K-22M; АEP40-016-65K-22M.

Automation Panels

Grantor (ADL, Russia)

U 1 x 220 V, 3 x 380 V

Applications: automation of heat supply station, lifting and transport mechanisms, technological processes, water treatment systems, cold supply systems, air conditioning and handling systems; automation units, etc.

Description:

Automation systems based on Grantor Control Panels and automatic equipment is a complex of panels what is used to control the entire technological process or any part of it. This complex is integrable in the existing Automated Process Control Systems (APCS).

Versions: local automation systems (to control a specific system) and upper level systems (to integrate several technological processes or circuits).

Automation panels and systems may be used to automate cyclic and continuous processes and specific process operations.

Pipeline Electric Gate Valve Applications

Grantor (ADL, Russia)

U 1 x 220 V, 3 x 380 V

I 0.1–1600 A

P 0.06–800 kW

Applications: automatic control of electric gate valves and flaps.

Description:

Two control modes for electric actuator of the gate valve: local and remote modes. Control panel is unified for any type of electrical actuators.

Control panel body material: high-quality plastic, IP54.

Functions of control panels for electrical gate valves: short-circuit protection (circuit breaker); overcurrent protection (configurable thermal relay); motor winding overheating protection (thermal relay is required); POWER, OPENED, CLOSED, ACCIDENT indicators on the front plate; dispatching: ACCIDENT, OPENEN, CLOSED (voltage-free contacts); possibility to connect a heating element to the electric actuator.

Short-circuit and fault monitoring option for control circuits of the fire fighting gate valves.

Control panels for fire fighting systems fulfill the the requirements of National State Standard (GOST R) 53325-2012.

Marking (example): АEP40-004-54-11Z.

Fire Fighting Applications

Grantor (ADL, Russia)

U 3 x 380 V

I 0.63–1600 A

P 0.37–800 kW

Applications: automatic control of fire extinguishing pumps.

Description:

Functionality options depending on applications: sprinkler or deluge fire fighting system.

Control panel offers two control modes: manual (local) and automatic modes.

In automatic mode, the ACTIVE/STANDBY operation scheme is activated: in case of failure of the active pump, the control panel will automatically turn on the standby pump (alarm light indicator will show the status of the relevant pump at the front plate of the panel).

Control panel provides expanded dispatching options. Alternative controls: two pressure relays (one standby relay) and dry running protection relay.

Products match the requirements of GOST R 53325-2012.

Marking (example): АEP40-037-54KP-21P1.

Sewage and Drainage Applications

Grantor (ADL, Russia)

U 1 x 220 V, 3 x 380 V

I 0.1–1600 A

P 0.06–800 kW

Applications: sewage and drainage systems, control of lift stations, sewage pumping stations.

Description:

Actuators: float gage control.

Control Panel functions: DRAINING/FILLING modes; automatic mutual backing-up of motors; connection of humidity sensors, thermal resistors (PTCs are available upon request); scheduled startup to protect the pump against stagnation; OVERFLOW indication and dispatching control.

Functions of Control Panels with soft starter: smooth start/stop of the pump; energy saving; protection of the system against surges occurred during starting/stopping of all pumps; starting current limitation; extended service life of the pump; (>25 A) protection against motor and soft starter overheating; (>25 A) protection against overload and underload; (>25 A) protection against overvoltage, voltage drop and rotor seizure.

Marking (example): АEP40-025-54KP-22U.

Frequency Control Panels

Grantor (ADL, Russia)

U 3 x 380 V

I 0.63–1500 A

P 0.37–800 kW

Applications: heat supply systems; hot and cold water supply systems; water supply and conditioning systems; circulating, boosting, borehole and feed pumps.

Description:

Intended to control a group of 1–6 pumps.

Versions: Control panel with a frequency converter (alternating master); control panel with a frequency converter for each motor.

Actuators: pressure sensor and dry running protection relay. Frequency control of pump sets allows to precisely maintain the preset system parameters at minimum motor losses.

Functions of Control Panels with frequency converter: frequency control of the operating pump; selection of the input analogue signal (from the sensor) [4..20] mA or [4..10] V; smooth start/stop of the pump; energy saving; protection of the system against surges occurred during starting/ stopping of all pumps; feedback by the signal of pressure sensor, pressure differential sensor, temperature sensor, etc.; version with a thermal resistor (upon request).

Marking (example): АEP40-025-54ChP-22А; АEP40-025-54Ch2-22А.

Relay Control Panels

Grantor (ADL, Russia)

U 1 x 220 V, 3 x 380 V

I 0.1–1600 A

P 0.06–800 kW

Applications: heat supply systems; hot and cold water supply systems; water supply and conditioning systems; circulating, boosting, borehole and feed pumps.

Description:

Intended to control 1, 2 and 3 single-phase and three-phase pumps (more pumps upon request). Versions with soft starters are available only for three-phase pumps (3 x 380 V, 3 x 690 V).

Actuators: pressure relay (or pressure sensor for three and more motors) and dry running protection relay. Pressure differential relay is available for two-motor panels (standard version).

Functions of Control Panels with soft starter: smooth start/ stop of the pump; pressure differential relay for two-pump panels; energy saving; protection of the system against surges occurred during starting/ stopping of all pumps; starting current limitation; extended service life of the pump; (>25 A) protection against motor and soft starter overheating; (>25 A) protection against overload and underload; (>25 A) protection against overvoltage, voltage drop and rotor seizure.

Marking (example): АEP40-037-54KP-22А.

Vacuum Breakers and Vacuum Control Valves

Mankenberg (Germany)

DN 20–250 mm

PN 0.6–4.0 MPa

t°op –40...+300°C

Connection type: Thread, Flanged, Welded.

Applications: heat and water supply systems; food and pharmaceutical industries, chemical industry and other sectors.

Description:

Vacuum breakers are intended to protect vessels and pipelines against vacuum which may caused by system draining, cooling down or pump deactivation.

Vacuum control valves are pressure reducing or overflow valves designed for controlling sub-atmospheric pressure (additional information is available upon request).

Deep drawing High Grade stainless steel contributes to higher performance indicators, including durability, corrosion resistance, service life, etc.

Body materials: Stainless Steel. Other materials are available upon request.

Connection flange materials: Carbon Steel, Stainless Steel.

Customized versions are available upon request.

Version: VV.

Surge Relief Valves

Mankenberg (Germany)

DN 100–400 mm

PN 1.6–16.0 MPa

t°op –40...+130°C

Connection type: Flanged.

Applications: trunk pipelines and liquid terminals.

Description:

Intended to relieve surges caused by closure/opening of valves or activation/deactivation of pumps, etc.

Single-seat direct-acting valves operate without any external energy supplies.

Activated by a surge, the valve opens to increase the capacity and closes up instantaneously to prevent any pressure drops. Water is discharged into a special storage vessel.

Surge relief valves may be fitted with a spring and pilot control systems.

Body materials: Carbon Steel, Stainless Steel. Other materials are available upon request.

Sealing materials: EPDM, FPM. Other materials are available upon request.

Pilot valve, distribution unit and internal parts material: Stainless Steel.

Version: SR.

Differential Pressure Valves

Mankenberg (Germany)

DN 15–800 mm

PN 1.6–2.5 MPa

t°op –10...+200°C

Connection type: Thread, Flanged, Welded.

Applications: heat and water supply systems; food and pharmaceutical industries, chemical industry and other sectors.

Description:

High precision control devices intended to maintain any preset differential pressure between two points in the system without external power supply (electricity). Deep drawing High Grade stainless steel contributes to higher performance indicators, including durability, corrosion resistance, service life, etc. Operating pressure range: standard pressure range, millibar pressure range and high pressure range.

Body materials: Carbon Steel, Stainless Steel (other options are available upon request).

Sealing materials: metal/metal, EPDM, FPM. Other materials are available upon request.

Sealed body with a drain hole and adjustment screw seal are available for toxic and hazardous applications. Customized versions are available upon request.

Version: DV.

Differential Pressure Valves

Granreg (ADL, Russia)

DN 15–100 mm

PN 1.6–4.0 MPa

t°max. +200°C

Connection type: Thread, Flanged, Welded.

Applications: steam and water systems, air supply systems.

Description:

Direct-acting differential pressure valves are high precision control devices intended to maintain any preset differential pressure between two points in the system without external power supply (electricity).

Body materials: Cast Iron, Carbon Steel, Stainless Steel.

Sealing materials: metal/metal, EPDM.

Versions with reduced flow coefficient are available upon request.

Version: KAT33, KAT35, KAT43, KAT44.

Pilot-Operated Control Valves

Granreg (ADL, Russia)

DN 40–800 mm

PN 1.6–2.5 MPa

t°op 0...+80°C

Connection type: Flanged.

Applications: water supply and sewage systems, fire fighting systems, industrial and agricultural technological processes.

Description:

Pilot-operated control valves are high precision control devices intended to perform the required functions.

Valves are controlled by fluid pressure or external source pressure.

Functionality depends on valve piping components.

Pilot piping with a built-in filter contributes to extended service life and higher reliability of the valve. All connections for pilot piping are made of stainless steel. Valves may come with a closing speed reducer designed to prevent surges.

Customized versions for operation under temperature of up to 130°С are available upon request.

Body materials: Cast Iron, Carbon Steel, Stainless Steel.

Sealing materials: EPDM.

Version: KAT10, KAT11, KAT20, KAT21.

Overflow Valves

Mankenberg (Germany)

DN 8–800 mm

PN 0.1–25.0 MPa

t°op –40...+400°C

Connection type: Thread, Flanged, Welded.

Applications: heat and water supply systems; food and pharmaceutical industries, chemical industry and other sectors.

Description:

High precision control devices are intended to maintain any preset pressure at the valve inlet without external power supply (electricity).

Deep drawing High Grade stainless steel contributes to higher performance indicators, including durability, corrosion resistance, service life, etc.

Body materials: Carbon Steel, Stainless Steel. Other materials are available upon request.

Sealing materials: metal/metal, EPDM, FPM. Other materials are available upon request.

Sealed body with a drain hole and adjustment screw seal are available for toxic and hazardous applications.

Customized versions are available upon request.

Version: UV.

Overflow Valves

Granreg (ADL, Russia)

DN 15–100 mm

PN 1.6–4.0 MPa

t°max. +200°C

Connection type: Thread, Flanged, Welded.

Applications: steam and water systems, air supply systems.

Description:

Direct-acting overflow valves are high precision control devices intended to maintain any preset pressure at the valve inlet without external power supply (electricity).

Body materials: Cast Iron, Carbon Steel, Stainless Steel.

Sealing materials: metal/metal, EPDM.

Versions with reduced flow coefficient are available upon request.

Version: KAT32, KAT42.

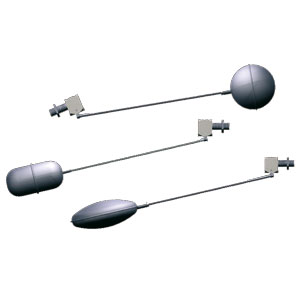

Float Valves

VYC (Spain)

DN 10–65 mm

PN 1.6 MPa

t°max. +200°C

Connection type: Thread, Flanged.

Applications: heat and water supplies.

Description:

Intended to maintain the required liquid level in the vessel.

Multiple combinations of different valves and floats match any project-specific flow and pressure requirements.

Body material: Stainless Steel.

Version: 151, 152.

Float Valves

Mankenberg (Germany)

DN 10–400 mm

PN 1.0–4.0 MPa

t°op –40...+300°C

Connection type: Thread, Flanged.

Applications: heat and water supply systems; food and pharmaceutical industries, chemical industry and other sectors.

Description:

Intended to maintain the required liquid level in the vessel. Standard versions are suitable for liquids with the minimum density of 960 kg/m3. Some versions come with a float rod (standard length of 1 m; other sizes are available upon request).

Deep drawing High Grade stainless steel contributes to higher performance indicators, including durability, corrosion resistance, service life, etc.

Body materials: Cast Iron, Carbon Steel, Stainless Steel. Other materials are available upon request.

Sealing materials: metal/metal, EPDM, FPM. Other materials are available upon request. Customized versions are available upon request.

Mounting options: internal (inside the vessel), external (on the vessel or pipeline).

Version: NV.

Pressure Reducing Valves

Mankenberg (Germany)

DN 8–800 mm

PN 1.0...31.5 MPa

t°op –40...+500°C

Connection type: Thread, Flanged, Welded.

Applications: heat and water supply systems; food and pharmaceutical industries, chemical industry and other sectors.

Description:

High precision control devices are intended to maintain any preset pressure at the valve outlet without external power supply (electricity).

Deep drawing High Grade stainless steel contributes to higher performance indicators, including durability, corrosion resistance, service life, etc.

Body materials: Carbon Steel, Stainless Steel. Other materials are available upon request.

Sealing materials: metal/metal, EPDM, FPM, NBR, CR. Other materials are available upon request.

Sealed body with a drain hole and adjustment screw seal are available for toxic and hazardous applications.

Customized versions are available upon request.

Version: DM.

Pressure Reducing Valves

Granreg (ADL, Russia)

DN 15–100 mm

PN 1.6–4.0 MPa

t°max. +230°C

Connection type: Thread, Flanged, Welded.

Applications: steam and water systems, air supply systems.

Description:

Direct acting pressure reducing valves are high precision control devices intended to maintain any preset pressure at the valve outlet without external power supply (electricity).

Body materials: Cast Iron, Carbon Steel, Stainless Steel.

Sealing materials: metal/metal, EPDM.

Versions with reduced flow coefficient are available upon request.

Version: KAT30, KAT40, KAT41.

Membrane Hydraulic Actuator Version

Milton Roy (France)

Qmax up to 16 000 l/s

Pmax up to 500 bar

Tmax. +320°С

Applications: water treatment and conditioning; chemical industry, food industry, pulp and paper industry.

Description:

High precision dosing (±1%) pumps coming with integrated safety valve

are suitable for pumping any fluids, including abrasive, crystallizing and high-viscosity media. Liquid end is made of different materials.

Options: Ex-proof motor; automatic capacity control; double membrane with a rupture sensor; up to 12 dosing heads; remote dosing head; special design valves; customized versions.

Versions: mROY, MaxROY, MilRoyal, PrimeRoyal.

Membrane Mechanical Actuator Version

Milton Roy (France)

Qmax up to 1200 l/s

Pmax up to 12 bar

Tmax. up to +50°С

Applications: water treatment and conditioning; chemical industry, food industry.

Description:

Membrane mechanical actuator ensures dosing accuracy of ±2%. Liquid end is made of different materials.

Options: Ex-proof motor, automatic capacity control (electrical servo motor and control unit). Double membrane with a rupture sensor, plunger stroke counter.

Version: G.

Membrane Solenoid Actuator Version

Milton Roy (France)

Qmax up to 76 l/s

Pmax up to 20.7 bar

Tmax. up to +50°С

Applications: water treatment and conditioning; chemical industry, pulp and paper industry.

Description:

Pumps with solenoid actuators offer a wide adjustment range due to manual or automatic change of stem stroke length and rate Liquid end is made of different materials.

Options: Ex-proof body; programmable microprocessor-based dosing; solution for pumping high-viscosity liquids (up to 10 000 cPs); venting or four-function valve.

Version: LMI.

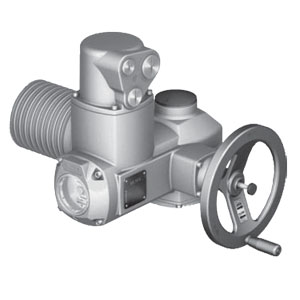

Multi-Turn Electric Actuators

Auma (Germany)

U 380/220 V

M 30–350 000 Nm

t°op –40…+50°С

Applications: heat and water supply systems, cooling and ventilation systems, industrial process systems; Ex-zones (upon request).

Description:

Intended to operate pipe valves and fittings in automatic mode. Actuators may be customized to meet almost any project-specific needs.

Designed for installation on KR Rubber Wedge Gate Valves and Orbinox Knife Gate Valves (actuator torque of up to 32 000 Nm).

Accessories: RWG Remote Position Indicator (4–20 mA), MWG Limit and Torque Transmitter (if AUMATIC Unit is available), Double/ Triple Limit and Torque Switches, Handweel Locking Device, DUO Intermediate Position Switch, Ex-proof version.

Actuator may be modified into a part-turn actuator by adding GS warm gear.

Enclosure class: IP68.

Version: SA.

Linear Electric Actuators

PS Automation (Germany)

U 220/24/380 V

F 1–25 kN

t°op –20…+80°С

Applications: ventilation systems, heat and water supply systems, cooling systems, industrial process systems.

Description:

PS Automation Linear Electric Actuators are designed for installation on Z-type Control Valves and Granreg Control Valves (КМ versions).

Accessories: potentiometer, positioner, position transmitter, auxiliary limit switches for three-position and analogue (4...20 mA) control.

Intellectual version PSL AMS coming with a microprocessor provides diagnostic options through computer synchronization.

PSL AMS supports auxiliary units, including PSIC Integrated Controller, Local Control Module with PSC.2 Display, PSCP Supercondenser Block for FailSafe function, etc.

Valve mounting kits are available upon request.

Enclosure class: IP65/67.

Version: PSL, PSL AMS.

Linear Electric Actuators

ADL (Russia)

U 24 V

F 450 N

t°op –20…+50°С

Applications: ventilation systems, heat and water supply systems, cooling systems.

Description:

AQT, AQM Linear Electric Actuators are designed for installation on Granreg Control Valves (КМ124Р, КМ324Р versions).

Different versions provide three-position and analogue (0(2)...10 V; 4...20 mA) control options.

Actuators come with a compact-size plastic body.

Valve mounting kits are available upon request.

Enclosure class: IP54.

Version: AQT, AQM.

Linear Electric Actuators

Schischek (Germany)

U 220/24 V AC/DC

F 0.5–10 kN

t°op –20…+50°С

Applications: Ex-zones; heat and water supply systems, cooling and ventilation systems, industrial process systems.

Description:

Schischek Linear Electric Actuators are designed for installation on Polna Two-Way and Three-Way Control Valves (Z type), Granreg Control Valves (KM version) and Schubert & Salzer Control Valves. Enclosure class: II 2G de IIC T5/T6.

Internal transformer provides 220 and 24 V supply. Special versions with optional controls are available upon request.

Actuators may come with a return mechanism with adjustable response speed, heating housing with independent power supply for aggressive climatic conditions and operating temperature of down

to –50°С, etc.

Valve mounting kits are available upon request.

Enclosure class: IP66.

Version: ExRun, RedRun, InRun.

Quarter-Turn Electric Actuators

Schischek (Germany)

U 220/24V AC/DC

M 5–150 Nm

t°op –40…+50°С

Applications: Ex-zones; heat and water supply systems, cooling and ventilation systems, industrial process systems.

Description:

Designed for installation on shut-off valves with 90° stem rotation — Beeval, Pekos, Schubert & Salzer and BV Ball Valves, as well as Granval and Stainval BC Butterfly Valves. Enclosure class: II 2G de IIC T5/T6.

Internal transformer provides 220 and 24 V supply. Special versions with optional controls are available upon request. Actuators may come with spring return mechanism, heating housing with independent power supply for aggressive climatic conditions and operating temperature of down to –50°С, etc.

Valve mounting kits are available upon request.

Enclosure class: IP66.

Versions: ExMax, RedMax, InMax.

Quarter-Turn Electric Actuators

Auma (Germany)

U 220/380 V

M 50–2400 Nm

t°op –40…+60°С

Applications: heat and water supply systems, cooling and ventilation systems, industrial process systems; Ex-zones (upon request).

Description:

Designed to rotate the valve stem less than 360° in automated mode (for example, gate valves or ball valves).

Intended for installation on: Granval and Swissfluid Butterfly Valves, Stainval BC and TM Valves; PEKOS and Beeval Ball Valves, BV17.

AUMA MATIC or AUMATIC integrated control units, position indicator, positioner, control cabinet and other accessories are available upon request.

Actuators may come with a heavy duty body for operation in aggressive media under high humidity and pollutant concentration conditions.

Enclosure class: IP67/68.

Version: SG, SQ.

Quarter-Turn Electric Actuators

PS Automation (Germany)

U 220/=24/~24/380 V

M 25-1000 Nm

t°op –20…+80°С

Applications: heat and water supply systems, cooling and ventilation systems, industrial process systems.

Description:

Designed for installation on shut-off valves with 90° stem rotation — Beeval, Pekos, Schubert & Salzer and BV Ball Valves, as well as Granval, Stainval and Swissfluid Butterfly Valves.

Wide range of accessories: potentiometer, positioner, position transmitter, auxiliary limit switches for three-position and analogue (4...20 mA) control.

Intellectual version PSQ AMS coming with a microprocessor provides diagnostic options due to synchronization with the Automated Process Control System (APCS) of the user. PSQ AMS options: PSIC Integrated Controller, Local Control Module with PSC.2 Display, PSCP Supercondenser Block for FailSafe function, etc.

Valve mounting kits are available upon request.

Enclosure class: IP65/67.

Versions: PSR-E, PSQ-E, PSQ, PSQ-AMS.

Electronic Relays

Fanox (Spain)

U 3х380 V

I ≤1000 A

Applications: fans, compressors, conveyors, press, three-phase and single-phase pumps.

Description:

Fanox Protection Relays are intended to protect the motor against underload, overload, phase shift and loss, as well as to provide thermistor protection option, etc.

Fanox motor protection solution is based on regulation of currents consumed by the motor. Three current are integrated into the protection relay. They measure consumed currents in non stop mode. Processed by electronic devices measurements are used to create a thermal model and to compare it with preset relay currents values.

Versions: С, GL, GEN, MT, PF.

Electronic Relays

Grancontrol (Italy)

U 200-480 V

I ≤1000 A

Applications: pumps, fans, lifting devices, air conditioners, conveyor belts, compressors, mixers, cranes, chillers, etc.

Description:

Grancontrol Protection Relays are designed for protecting consumers against overvoltage, undervoltage, phase shift or loss in three-phase voltage networks.

As compared to thermal relays, Grancontrol Protection Relay provides higher precision, improved reliability and longer service life. It is possible to match corresponding relay depend on application and project requirements considering Ip adjustable current setting range.

Versions: P40, VRА.

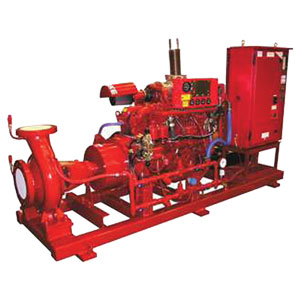

Fire Pumping Stations

SPP (England)

Q 50–1200 m3/h

H 20–1000 m

Actuator: diesel, electrical types.

Applications: fire fighting systems for supplying water to automatic fire extinguishing units, hose reels or fire hydrants.

Description:

Pumps come with power units, control systems, fuel tanks and industrial silencers.

Features: pumps match NFPA requirements; easy installation and maintenance; designed for commercial and industrial applications; compact size.

Certification: UL, FM. Meets the Fire Safety Regulations.

Grooved Couplings

Reliable (USA)

DN 25–600 mm

PN 1.6/2.07/3.45 MPa

Applications: fire protection systems: sprinkler water-filled and alternate wet and dry pipe systems, deluge systems and foam extinguishing systems;

construction of tunnels, bridges, shafts; heating and air conditioning systems;

draining and treatment of liquids in pipelines and pneumatic systems;

delivering pipeline systems for snowmakers.

Description:

Grooved products are used in systems of pipelines with grooved ends. This solution is more cost effective and reliable as compared to welded or flanged joints.

Material: Malleable Cast Iron.

Certification: UL, FM, Vds. Meets the Fire Safety Regulations.

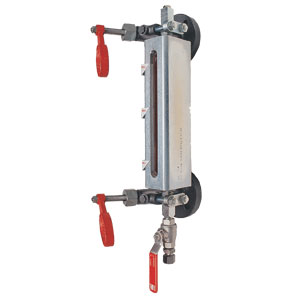

Fire Fighting System Control Module

Reliable (USA)

DN 65–200 mm

PN 1.2/2.07 MPa

Connection type: Flanged, Grooved Coupling, Flanged/Grooved Coupling.

Description:

Reliable Control Modules are used in water and foam fire fighting systems to supply extinguishing fluid and to activate electrical and hydraulic fire alarm devices in automatic mode.

Mounting options: vertical/horizontal.

Certification: UL, FM, Vds, LPCB. Meets the Fire Safety Regulations.

Types: E (water versions), D and DDX (water and air versions), DDX (deluge versions).

Fire Sprinklers, ESFR

Reliable (USA)

К–Factor 200/242/320/363

t°resp 74, 100°C

Style: Pendant.

Description:

JL-14 Sprinklers: used in warehouses with stored materials packed in bags and stacked on pallets.

JL-17 Sprinklers: used for protection of high-bay warehouses without rack-stack mounted sprinklers.

HL-22 Sprinklers: used for protection of warehouses with the ceiling height of up to 14.6 m and stocking height of up to 13 m.

N25 Sprinklers: used in warehouses with the stocking height of up to 10.7 m.

Joint: 3/4'' — JL-14, JL-17; 1'' — HL-22, N25.

Colour: Bronze, White.

Response: quick.

Coverage: extended.

Working mechanism: fusible element.

Certification: UL, FM, Vds, LPCB. Meets the Fire Safety Regulations.

Versions: JL-14, JL-17, HL-22, N25.

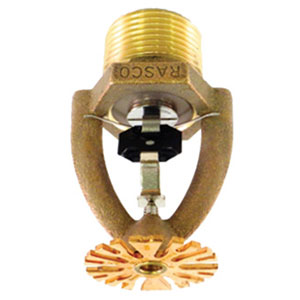

Fire Sprinklers, 3/4''

Reliable (USA)

К–Factor 115/118/160/200

t°resp 57–182°C

Style: Pendent, Upright, Conventional, Horizontal Sidewall.

Description:

Sprinklers are used in water and foam fire fighting systems for fire extinguishing and confinement.

Special design and manufacturing technology ensures high tightness of the sprinklers. Product performance depends on orifice diameter.

K-Factor: 115, 118; 160 — G XLO, Upright; 200 — G VELO, Pendant.

Joint: 3/4''.

Colour: Bronze, Chrome, White.

Response: standard, quick.

Coverage: standard, extended (G XLO, G VELO).

Working mechanism: cup, fusible element (G XLO, G VELO).

Certification: UL, FM, Vds. Meets the Fire Safety Regulations.

Fire Sprinklers, 1/2''

Reliable (USA)

К–Factor 40, 60, 80

t°resp 57–182°C

Style: Pendent, Upright, Conventional, Horizontal Sidewall, Concealed.

Description:

Sprinklers are used in water and foam fire fighting systems for fire extinguishing and confinement.

Special design and manufacturing technology ensures high tightness of the sprinklers.

Product performance depends on orifice diameter.

Joint: 1/2''.

Colour: Bronze, Chrome, White.

Response: standard, quick.

Coverage: standard.

Working mechanism: cup.

Certification: UL, FM, Vds. Meets the Fire Safety Regulations.

Water Heaters and Storage Vessels

Flamco (the Netherlands)

DN 120–3000 mm

PN 1.0/1.6* MPa

t° 95/110*°C

Applications: drinking water systems; heating and heat supply systems.

Description:

Water heaters feature thermal insulation (made of Polyurethane Foam) with easy clean synthetic coating for minimum heat loss. Internal coating of the vessel is made of high quality enamel.

Duo Water Heaters come with integrated pressure gauges and magnesium anode for corrosion protection and minimum calcium deposition.

Heating element reaching the bottom of the vessel ensures heating of maximum water volume and prevents bacteria formation. Insulation is made of HCFC-free solid foam material free with the thickness of 50 mm (with easy clean plastic coating).

Medium: water.

*Vessel/coil.

Versions: Duo, PS, Supastor.

Pressurisation Automats

Granlevel (ADL, Russia)

V 150–5000 l

PN 1.0/1.6 MPa

t° 70°C

Applications: closed-loop heating and cooling systems (for maintaining constant pressure, compensating temperature expansions of water, deaerating and compensating heat carrier losses).

Description:

Granlevel Pressurisation Automats maintain the required system pressure within a narrow range (± 0.02 MPa) in all operating modes and compensate thermal expansion of the heat carrier in heating and cooling systems.

Standard version features the following components: membrane expansion vessel, control unit, vessel connection.

MODBUS Interface is used to monitor and control the system. Controller with Russian menu ensures intuitive control of the automats. Pressurisation automats are designed for systems filled with ethylene glycol (up to 30%) / water mixtures.

Versions: based on DPV2, DPV4 and DPV6 pumps.

Expansion Vessels

Granlevel (ADL, Russia)

V 2–15 000 l

PN 0.6/1.0/1.6/2.0 MPa

t° 75°C

Type: vertical/horizontal.

Applications: heating and cooling systems; hot and cold water supply systems.

Description:

HM-Type Vessels — with non-replaceable membrane for heating and cooling systems; M-Type Vessels — with replaceable membrane for heating and cooling systems; A-Type Vessels — hydraulic accumulators with replaceable membrane for water supply systems.

Expansion vessels are designed for compensating temperature expansion of the heat carrier.

Hydraulic accumulators serve to prevent surges, accumulate water reserves and protect pumps against frequent activation/deactivation.

Vessels may accommodate ethylene glycol (up to 50%) water mixtures.

Versions: НМ, М, А.

Multipurpose Frequency Converters

Grandrive (ADL, Russia)

U 380 V

I 2.3–24 A

P 0.75–11 kW

Applications: water treatment plants; sewage networks; water conditioning; water intake; hydro power plants (for heat and water supply systems, ventilation and air conditioning systems), etc.

Description:

Designed specially for 0.75...11 kW asynchronous motors.

Frequency converter (FC) is able to control the motor in scalar and vector modes.

Control desk is equipped with a built-in potentiometer for easier regulation of the output frequency.

Key advantages: integrated electromagnetic interference filter (EMI-filter) of Category 1; integrated PID-controller (accurate control of preset process); V/Hz or vector control mode; automatic restarting; starting up of rotating motor; sleep mode; enclosure class - IP20.

Versions: PFD20, PFD50, PFD55.

Medium Voltage Frequency Converters

Grandrive (RXPE)

U 3, 6, 10, 13.8 kV

I 30–850 A

P up to 12 500 kW

Applications: startup, stop, protection and control of standard asynchronous and synchronous motors with the voltage exceeding 1000 V.

Description:

Multi-level architecture. Standardized power cells allow to avoid adding new items to SPTA kits.

Due to smooth sine wave at the output of the frequency converter, no additional devices are required for handling long cables.

Power cells with recuperation provided for heavy loads in generator mode allow to deliver generated power to the supply mains. Power part is electrically and physically isolated from the control system. Fast-acting fibre optical channels are used to control power cells.

Control desk in Russian language .

Enclosure class — IP21 (IP54 and container version are available upon request).

Customized high-power versions are available upon request.

Versions: RMVC4000, RMVC5000.

Highly Intelligent Applications

Emotron (CG D & A, Sweden)

U 380/690 V

I 3–3000 A

P 0.75 kW–3 MW

Applications: chemical industries, food industry, pulp and paper industry, mining; earthmoving, crane and lifting equipment; power manipulator mechanisms.

Description:

Multi-purpose frequency converters designed for precision regulation of asynchronous motor speed. Innovative DTC technology (Direct Torque Control) is used to regulate highly dynamic mechanisms, maintain high peak torque at low speed and ensure immediate soft startup and stop.

Key advantages: up to 28 task speeds; mechanical brake control option; increased peak torque; vector braking; full protection range and automatic motor restart option; selection of process-specific units of measurement (bar, m3/s, etc.); electronic load monitoring; integrated PID-controller; crane options; enclosure class — IP20 or IP54.

Version: VFX 2.0.

General Industrial Frequency Converters

Emotron (CG D & A, Sweden)

U 380/690 V

I 3–3000 A

P 0.75 kW–3 MW

Applications: water supply and wastewater treatment plants (lifting stations I–II, sewage pumping stations/water treatment plants); heating networks (smoke exhaust); CHP (discharging); boiler houses (heat carrier feed pumps); central heating stations; domestic heating plants; food industry; air conditioners; conveyors, transporters, etc.

Description:

Intended to control pumps, fans, compressors, etc. Frequency converters regulate motor speed for decreasing power consumption and ensure smooth startup/stop of the equipment for longer service life and lower maintenance costs.

Frequency converters (from 160 kW) are independent power modules without integration by DC link.

Key advantages: control of the groups of up to 7 motors; integrated load monitor; sleep mode; starting up of rotating motor; enclosure class - IP20 or IP54.

Version: FDU 2.0.

Penstock

Orbinox (Spain)

Sizes 150 х 150...

2000 х 2000*

PN 6/10 mwc

Connection type: channel or wall mounting.

Applications: water treatment plants, sewage systems, water conditioning systems, irrigation, water intake facilities, hydroelectric power plants.

Description:

Bidirectional Penstock fitted with resilient seal packing (three sides with CC-type packing and four sides with MU-type packing) are intended for open channel, wall or wall adaptor mounting.

Sluice valve body design ensures an easy and quick installation.

The interior design solution prevents the build up of foreign particles which impede the closure of the valve.

Frame and sluice materials: Stainless Steel. Other materials are available upon request.

Seat seal material: EPDM.

Actuators: manual control (handwheel with/without stem extension, gearbox with/without stem extension), servo actuators (electric actuator, pneumatic actuator, hydraulic actuator).

Versions: CC, MU.

Unidirectional Knife Gate Valves Vessel Insulation Applications

Orbinox (Spain)

DN 80 mm

PN 1.0 MPa

Рop 1.0 MPa

Connection type: Wafer.

Applications: food industry, chemical industry, mining, pulp and paper industry, etc.

Description:

Intended for isolating storage vessels and main system. Unidirectional Knife Gate Valves enable to service the connected system without emptying the vessel. The interior design solution prevents the build up of foreign particles which impede the closure of the valve.

Solid cast body wedges and guides ensure secure closure of the gate valve.

Body material: Stainless steel CF8M.

Knife material: Stainless Steel (other options are available upon request).

Seat seal material: EPDM, Nitrile, metal-to-metal, Viton, Silicon, PTFE.

Actuators: Valves come with a handle and ratchet wheel.

Versions: KP.

Unidirectional Knife Gate Valves High Pressure Applications

Orbinox (Spain)

DN 80–3000 mm

Рop 10.0–1.0 MPa

Connection type: Wafer.

Applications: water treatment plants, domestic waste water and sewage systems; food industry, chemical industry, mining, pulp and paper industry, energy sector, etc.,

Description:

Design of the valve body and seat seal prevents clogging of the gate with suspended solids.

Body material: Carbon Steel (other options are available upon request).

Knife material: Stainless Steel (other options are available upon request).

Seat seal material: EPDM, metal/metal.

Actuators: manual control (handwheel with stem extension, bevel-type gearbox), servo actuators (electric actuator, pneumatic actuator, hydraulic actuator).

No standard version is available (valve design depends on project-specific operating pressure).

Versions: CW, WS.

Hopper Knife Gate Valves

Orbinox (Spain)

DN 50–600 mm

PN 1.0 MPa

Рop 0.3–0.1 MPa

Connection type: Wafer.

Applications: energy sector, chemical industry, food industry, mining.

Description:

Intended for shutting off the flow of the abrasive medium in hopper systems (palletized and powder media). Special body design contributes to quick and smooth movement of the medium and allows to use the gate as a round (XC) or rectangular (BC) bleed hopper valve.

Body material: Cast Iron, Stainless Steel (XC, BC), Carbon Steel (BC).

Knife material: Stainless Steel. Other materials are available upon request.

Seat seal material: metal/metal, EPDM, Nitrile, Viton, Silicon, PTFE.

Actuators: manual control (handwheel with/without stem extension, chain-, lever- and bevel-type gearbox), servo actuators (electric actuator, pneumatic actuator, hydraulic actuator).

Versions: XC, BC.

Bidirectional Knife Gate Valves

Orbinox (Spain)

DN 50–1200 mm

PN 1.0 MPa

Рop 1.0–0.2 MPa

Connection type: Wafer.

Applications: water treatment plants, domestic waste water and sewage systems; chemical industry, mining, metallurgy, food industry, pulp and paper industry.

Description:

Double-seat design guarantees tight shut-off of direct and return flows of the medium. Valve is suitable for shutting off the flow for transportation of abrasive slurry (VG) and viscous media (TL, TK).

Body material: Cast Iron, Stainless Steel. Other materials are available upon request.

Knife material: Stainless Steel. Other materials are available upon request.

Seat seal material: metal/metal (except for EB), EPDM, Nitrile, Viton, Silicon, PTFE, natural rubber.

Actuators manual control (handwheel with/without stem extension, chain-, lever- and bevel-type gearbox), servo actuators (electric actuator, pneumatic actuator, hydraulic actuator).

Versions: EB, VG, TL, TK.

Unidirectional Knife Gate Valves

Orbinox (Spain)

DN 50–1200 mm

PN 1.0 MPa

Рop 1.0–0.2 MPa

Connection type: Wafer.

Applications: water treatment plants, domestic waste water and sewage systems; mining, pulp and paper industry, chemical industry, food industry; cement production; energy sector, etc.

Description:

Design of the body and seat seal of Orbinox gate valves prevents clogging of the gate with suspended solids.

Body material: Cast Iron, Stainless Steel. Other materials are available upon request.

Knife material: Stainless Steel. Other materials are available upon request.

Seat seal material: metal/metal, EPDM, Nitrile, Viton, Silicon, PTFE.

Actuators: manual control (handwheel with/without stem extension, chain-, lever- and bevel-type gearbox), servo actuators (electric actuator, pneumatic actuator, hydraulic actuator).

Versions: EX, ET, EK.

Horizontal Multistage Pumps

Ebara (Japan/Italy)

Q up to 27 m3/h

H up to 100 m

Applications: water supplies; irrigation and flooding; conditioning and water treatment, etc.

Description:

Centrifugal pumps are coming with horizontal shaft and end seal.

Temperature and pressure ranges: –15...+110°С, PN 10.

Body material: Stainless steel, Cast Iron.

Impeller materials: Stainless steel, Technopolymer.

Pumps come with 2900 rpm motors.

Horizontal multistage centrifugal pumps with durable and compact design are suitable for boosting systems, auto washing, industrial plants, water treatment, cold and hot water supply systems, conditioning, irrigation and stormwater distribution systems.

Versions: COMPACT, MATRIX.

Horizontal Multistage Pumps with Electric Actuators

Caprari (Italy)

Q up to 600 m3/h

H up to 1000 m

Applications: fire fighting, water supplies, irrigation and flooding; medium and large-scale heating systems and air conditioning systems; civil water supplies; boosting systems; snowmaking.

Description:

Centrifugal pumps are coming with horizontal shaft with an end seal or gland seal.

Temperature and pressure ranges: –10...+90°С,

PN 100.

Body material: Cast Iron.

Impeller materials: Cast Iron, Stainless Steel, Bronze.

Sealing material: Graphite/ Silicone Carbide (Graphite Packing Cord).

Pumps operating at maximum efficiency come with IP55 motors (2900 and 1450 rpm versions).

Some versions are fitted with a pressure balancer. The end seal may be replaced with gland packing and vice versa. Flexible coupling is used to connect the hydraulic end with the motor.

Versions: HMU, MEC-MR, PM.

Horizontal Two and Three Stage Pumps with Diesel Actuators

Caprari (Italy)

Q up to 252 m3/h

H up to 193 m

Applications: water supply systems, fire fighting, irrigation, other water supply applications with diesel engines used as actuators.

Description:

Centrifugal pumps are coming with horizontal shaft and gland packing seal.

Temperature and pressure ranges: –10...+90°С,

PN 16.

Body material: Cast Iron.

Impeller materials: Cast Iron.

Packing: Graphite Cord.

Pumps fitted with reinforced bearings and supports for secure connection with flanged flywheel of SAE3 diesel engine. Products feature a suction pipe, vaned diffuser, volute casing, bearing housing, grey cast iron impeller and stainless steel shaft.

Flexible coupling is available upon request (please, specify connecting dimensions of the flywheel in your order).

Versions: MEC-MG.

Horizontal Single Stage Self-Priming Pumps

Ebara (Japan/Italy)

Q up to 4.5 m3/h

H up to 59 m

Applications: fire fighting, water supplies, irrigation and flooding, conditioning, etc.

Description:

Centrifugal pumps are coming with horizontal shaft and end seal.

Temperature and pressure ranges: +5...+45°С, PN 6.

Body material: Stainless Steel.

Impeller materials: Stainless

Steel, Technopolymer.

Sealing: end seal.

Pumps come with 2900 rpm motors.

Stainless steel pumps provide significant advantages as compared to standard cast iron solutions, including high efficiency due to smooth surface of components and low friction losses.

Patented production lines of casting, stamping and welding of pump bodies and impellers should be specially noted.

Versions: JE(X), JES(X).

Horizontal Single Stage Pumps

Ebara (Japan/Italy)

Q up to 240 m3/h

H up to 95 m

Applications: fire fighting, hot and cold water supply, air conditioning, heating, etc.

Description:

Centrifugal pumps are coming with horizontal shaft and end seal.

Temperature and pressure ranges: –10...+110°С.

Body material: Stainless Steel.

Impeller materials: Stainless Steel.

Pumps come with 2900 and 1450 rpm motors.

Wide range of stainless steel pumps provide significant advantages as compared to standard cast iron solutions, including high efficiency due to smooth surface of components and low friction losses. Patented production lines of casting, stamping and welding of pump bodies and impellers should be specially noted.

Versions: CD(X), 2CDX, 3M, 3LM, 3LS, DWO.

Horizontal Single Stage Pumps with Electric Actuators

Caprari (Italy)

Q 1200 m3/h

H up to 140 m

Applications: fire fighting, water supplies, irrigation and flooding; medium and large-scale heating systems and air conditioning systems; civil water supplies; boosting systems.

Description:

Centrifugal pumps are coming with horizontal shaft with mechanical seal or gland packing seal.

Temperature and pressure ranges: –10...+90°С,

PN 16.

Body material: Cast Iron.

Impeller materials: Cast Iron, Stainless Steel, Bronze.

Sealing material: Graphite/Silicone Carbide (Graphite Packing Cord).

Pumps operating at maximum efficiency come with IP55 motors (2900 and 1450 rpm versions).

Some versions are fitted with a pressure balancer. By reinstalling several parts, the end seal may be replaced with gland packing.

Versions: NC, MEC-A.

Dirt Separators

Flamco (the Netherlands)

DN 20–600 mm

PN 1.0/1.6/2.5 MPa

t° –10...120°C

Connection type: Welded, Thread, Flanged.

Applications: closed-loop heating and cooling systems.

Description:

PALL rings provide larger contact surface for trapping and removing solid particles to the lower part of the separator.

Stainless steel PALL rings have an extended service life.

Due a large-sized Flamco Clean lower chamber, no daily draining of the sediments is required. The above elongated chamber with still water is used for sedimentation of solid particles. No water swirling and disturbance which may remove solid particles back to the system occur in this part.

Turn the ball valve to drain the sediments.

Versions: Flamco Clean.

Air and Dirt Separators

Flamco (the Netherlands)

DN 20–600 mm

PN 1.0/1.6/2.5 MPa

t° –10...120°C

Connection type: Welded, Thread, Flanged.

Applications: closed-loop heating and cooling systems.

Description:

Separators are based on a brand new PALL ring solution. Air bubbles present in the fluid adhere to the surface of the PALL rings thus forming larger bubbles which detach from the rings and reach the air chamber for further release into the atmosphere. The product range features separators with upper air chamber and lower chamber intended for sedimentation and removal of solids present in the heat carrier. Bottom drain valve is used to wash off the collected particles. Particles escaped from the lower chamber come to the surface and are removed by the flush valve.

Material: Brass, Steel.

Medium: water and ethylene glycol (up to 50%) water mixtures.

Maximum flow rate: 1.5 m/s.

Versions: Flamcovent, Flamcovent Clean.

Centrifugal Air Separators

Flamco (the Netherlands)

DN 25–600 mm

PN 1.0/1.6/2.5 MPa

t° –10...120°C

Connection type: Welded, Thread, Flanged.

Applications: closed-loop heating and cooling systems.

Description:

Designed for complete removal of air and solid particles from heating and cooling systems to increase heat carrier flow, system performance and service life of system equipment. Air separators rely on centrifugal force as a basic principle of operation. Tangential position of separator fittings contributes to liquid swirling with heavy fraction (liquid) pressed against the separator's walls and light fraction (air) accumulated inside the body. The upper part of the separator is fitted with a automatic air for automatic release of air into the atmosphere.

Material: Steel.

Medium: water and ethylene glycol (up to 50%) water mixtures.

Maximum flow rate: 5 m/s.

Versions: Flexair.

Three-Way Control Valves

Polna (Poland)

DN 15–250 mm

PN 1.6–40.0 MPa

t°op –10...+300°C

Connection type: Flanged.

Applications: heat, water supply systems; chemical industry and other sectors.

Description:

Three-way single-seat control valves fitted with electric or pneumatic actuators. Intended for mixing (Z3M) or separating (Z3R) solid-free liquid flows.

Valve liquid pressure drop shall not exceed 1.6 MPa. Otherwise a stellite seat shall be used.

Body materials: Cast Iron, Carbon Steel, Stainless Steel. Other materials are available upon request.

Internal parts material: Stainless Steel.

Sealing materials: PTFE, Graphite, Stainless Steel.

Customized versions for aggressive and contaminated media, higher temperatures and pressures are available upon request.

Mounting options: horizontal or vertical pipeline with actuator in upper or lateral position.

Version: Z3.

Three-Way Control Valves

Granreg (ADL, Russia)

DN 15–65 mm

PN 1.6 MPa

t°op –20...+130°C

Connection type: Thread.

Applications: heat and water supply systems, ventilation systems.

Description:

KM324R Three-Way Control Valve is a control valve fitted with a linear electric actuator. Intended for mixing and separating liquid flows.

Valve liquid pressure drop shall not exceed 1.6 MPa.

Body materials: Brass.

Internal parts material: AISI304 Stainless steel.

Mounting options: horizontal or vertical pipeline with actuator in upper or lateral position.

Version: KM324R.

Three-Way Control Valves

Granreg (ADL, Russia)

DN 15–300 mm

PN 1.6 MPa

t°op –10...+230°C

Connection type: Flanged.

Applications: heat and water supply systems, ventilation systems.

Description:

Three-way control valves KM307F and KM317F come with linear electric actuators.

KM307F versions are designed for mixing liquid flows; KM317F are designed for separating liquid flows.

MX mounting kit is required for PSL and PSL-AMS electric actuators.

Valve liquid pressure drop shall not exceed 1.6 MPa.

Body materials: Carbon Steel.

Internal parts material: Stainless Steel.

Sealing materials: Stainless Steel.

Mounting options: horizontal or vertical pipeline with actuator in upper or lateral position.

Versions: KM307F, KM317F.

Two-Way Control Valves

Polna (Poland)

DN 15–250 mm

PN 1.6–40.0 MPa

t°op –10...+300°C

Connection type: Flanged.

Applications: heat, water supply systems; chemical industry and other sectors.

Description:

Intended to control solid-free liquid flows.

Single-seat two-way control valves are fitted with electric or pneumatic actuators.

Valve liquid pressure drop shall not exceed 1.6 MPa. Otherwise a stellite seat shall be used.

Body materials: Cast Iron, Carbon Steel, Stainless Steel. Other materials are available upon request.

Internal parts material: Stainless Steel.

Sealing materials: PTFE, Graphite, Stainless Steel.

Customized versions for aggressive and contaminated media, higher temperatures and pressures are available upon request.

Mounting options: horizontal or vertical pipeline with actuator in upper or lateral position.

Version: Z.

Two-Way Control Valves

Granreg (ADL, Russia)

DN 15–200 mm

PN 1.6 MPa

t°op –20...+200°C

Connection type: Thread, Flanged.